Unit cost#

This section computes engineering, tooling, manufacturing labour, and many other costs associated with developing, certifying, and producing the example airplane. These costs are combined to compute minimum selling price for the airplane. Finally, a break-even analysis is performed to determine an appropriate unit cost for the airplane. The first step is to estimate the number of work hours for engineering, tooling, and manufacturing using the statistical relations. Then, the dollar amount can be computed by multiplying the number of hours by appropriate rates in dollars per hour. Refer to section 2.2 in Gudmundsson for more details. The following subsections compute the work hours and the corresponding costs.

Various quantities are required for computing the cost. Below table summarizes the quantities used in cost estimation. Note that the structural weight of the airframe consists of empty weight minus engine, avionics, seats, furnishings, control systems, and other components. In this demonstration, it is computed as 65% of the empty weight but it can be directly obtained from weight and balance studies. The testing and certification cost depends on the number of prototypes built before actual production starts. In this section, the number of prototypes is assumed to be 3.

The cost relations outlined in Gudmundsson are referenced at 2012 dollar value. This needs to be updated to current dollar value using consumer price index (CPI) which measures average change in price over time. The CPI factor is calculated using US Bureau of Labor Statistics’ inflation calculator. Finally, the dollar rate per hour for engineering, tooling, and manufacturing is set to 92, 61, and 53 dollars/hr, respectively, based on the values provided in Gudmundsson’s book.

Parameter |

Value |

Source |

|---|---|---|

Airframe weight |

2234 lbs |

computed |

Max level speed |

210 kts |

V-n diagram |

Aircraft produced in 5-year period |

1000 |

assumed |

Consumer price index |

1.4 |

computed |

Number of prototypes |

3 |

assumed |

Number of engines |

2 |

mission requirement |

Max engine power |

360 hp |

from trade study |

Propeller diameter |

6.25 ft |

from trade study |

Engineering rate |

$92/hr |

Gudmundsson, section 2.2.2 |

Tooling rate |

$61/hr |

Gudmundsson, section 2.2.2 |

Manufacturing rate |

$53/hr |

Gudmundsson, section 2.2.2 |

Below code block imports required libraries and defines above variables:

import matplotlib.pyplot as plt

import numpy as np

# Variables

W_airframe = 2234 # lbs, get this value from weights

VH = 210 # ktas

N = 1000 # units for next 5 year

Qm = N/60 # production rate, per month

Np = 3 # number of prototypes

N_engine = 2 # number of engines

Pbhp = 720 / N_engine # bhp

Dp = 6.34 # ft

CPI = 1.4 # CPI factor

R_engg = 92 # $/hr

R_tool = 61 # $/hr

R_manf = 53 # $/hr

Work hours#

The work hours are estimated using equation 2.2, 2.3, and 2.4 from Gudmundsson’s book. For brevity, equations are not reproduced here. In these equations, several fudge factors are used to accomodate factors such as amount of composites in airframe and certification type. Below code block defines these factors, refer to section 2.2.2 in Gudmundsson’s book for further details.

# Fudges factors for work hour calculations

F_cert = 1 # 14 CFR Part 23

F_cf = 1

F_comp = 1 # all aluminium frame

F_press = 1 # no pressurization

F_taper = 1 # taper wing

Below code block computes work hours for engineering, tooling, and manufacturing. It also computes average time required to build an airplane. Note that this average is computed over a 5-year period, it may take a lot longer to build a single plane during early days of production.

# engineering hours

H_eng = 0.0396 * W_airframe**0.791 * VH**1.526 * N**0.183 * F_cert * F_cf * F_comp * F_press

# tooling hours

H_tool = 1.0032 * W_airframe**0.764 * VH**0.899 * N**0.178 * Qm**0.066 * F_taper * F_cf * F_comp * F_press

# manufacturing hours

H_manf = 9.6613 * W_airframe**0.74 * VH**0.543 * N**0.524 * F_cert * F_cf * F_comp

# average time

avg_build_time_unit = H_manf / N

print(f"Engineering hours: {int(H_eng):,} hrs")

print(f"Tooling hours: {int(H_tool):,} hrs")

print(f"Manufacturing hours: {int(H_manf):,} hrs")

print(f"Average build time for an airplane: {int(avg_build_time_unit):,} hrs")

Engineering hours: 218,537 hrs

Tooling hours: 182,980 hrs

Manufacturing hours: 1,978,436 hrs

Average build time for an airplane: 1,978 hrs

Fixed cost#

Based on the work hours comptued in previous section, different costs are computed using equations 2.5 - 2.13 in Gudmundsson’s book. Below code block computes fixed cost i.e the cost associated with engineering, development, flight testing, and tooling. These costs are also known as non-recurring costs.

# engineering cost

C_engg = 2.0969 * H_eng * R_engg * CPI

# development cost

C_dev = 0.06458 * W_airframe**0.873 * VH**1.89 * Np**0.346 * CPI \

* F_cert * F_cf * F_comp * F_press

# flight test operations cost

C_ft = 0.009646 * W_airframe**1.16 * VH**1.3718 * Np**1.281 * CPI * F_cert

# tooling cost

C_tool = 2.0969 * H_tool * R_tool * CPI

# fixed cost or certification cost

C_cert = C_engg + C_dev + C_ft + C_tool

print(f"Engineering cost: ${int(C_engg):,}")

print(f"Development support cost: ${int(C_dev):,}")

print(f"Flight test operations cost: ${int(C_ft):,}")

print(f"Tooling cost: ${int(C_tool):,}")

print(f"Total fixed cost: ${int(C_cert):,}")

Engineering cost: $59,022,853

Development support cost: $2,716,777

Flight test operations cost: $648,969

Tooling cost: $32,767,236

Total fixed cost: $95,155,837

Variable cost#

Below code block computes variable costs i.e. the cost which depends on the number of units produced. These costs are also known as recurring costs. It also computes the variable cost per unit airplane produced. The cost of the avionics is assumed to be $15,000 in 2012 dollar value. However, a better estimate should be used if available.

# manufacturing cost

C_manf = 2.0969 * H_manf * R_manf * CPI

# quality control cost

C_qc = 0.13 * C_manf * F_cert * F_comp

# material cost

C_mat = 24.896 * W_airframe**0.689 * VH**0.624 * N**0.792 * CPI * F_cert * F_cf * F_press

### per aircraft cost

# avionics

C_avionics = CPI * 15000

# engine

C_engine = 174 * N_engine * Pbhp * CPI

# propellor

C_prop = 209.66 * N_engine * CPI * Dp**2 * (Pbhp/Dp)**0.12

# avg unit cost

unit_var_cost = (C_manf + C_qc + C_mat) / N + C_engine + C_prop + C_avionics

print(f"Manufacturing labor cost: ${int(C_manf):,}")

print(f"Quality control cost: ${int(C_qc):,}")

print(f"Material cost: ${int(C_mat):,}")

print(f"Avionics cost for each unit: ${int(C_avionics):,}")

print(f"Engine cost for each unit: ${int(C_engine):,}")

print(f"Propeller cost for each unit: ${int(C_prop):,}")

print(f"Unit variable cost: ${int(unit_var_cost):,}")

Manufacturing labor cost: $307,824,948

Quality control cost: $40,017,243

Material cost: $47,297,779

Avionics cost for each unit: $21,000

Engine cost for each unit: $175,392

Propeller cost for each unit: $38,314

Unit variable cost: $629,845

Unit cost & Selling price#

Once fixed and variable costs are computed, next step is to estimate the minimum selling price. The total unit cost (also known as the minimum cost to produce an airplane) is simply the sum of the unit fixed and variable cost. The minimum selling price is obtained by adding manufacturer liability insurance to this unit total cost. Based on the values provided in Gudmundsson, approximately 15% liability insurance is assumed.

Below code block computes unit cost and minimum selling price:

# total_unit_cost

total_unit_cost = C_cert / N + unit_var_cost

# liability insurance

liability_ins = round(0.15 * total_unit_cost,-4)

# minimum selling price

min_selling_price = total_unit_cost + liability_ins

print(f"Unit total cost: ${int(total_unit_cost):,}")

print(f"Liability insurance: ${int(liability_ins):,}")

print(f"Minimum selling price: ${int(min_selling_price):,}")

Unit total cost: $725,001

Liability insurance: $110,000

Minimum selling price: $835,001

Below table summarizes the cost analysis for the example airplane:

Cost type |

Cost/unit ($) |

|---|---|

Engineering |

59,023 |

Development support |

2,717 |

Flight test operations |

649 |

Tooling |

32,767 |

Fixed cost |

95,156 |

Manufacturing labor |

307,825 |

Quality control |

40,017 |

Material |

47,298 |

Avionics |

21,000 |

Engines |

175,392 |

Propeller |

38,314 |

Variable cost |

629,845 |

Total cost to produce |

725,001 |

Manufacturer’s liability insurance |

110,000 |

Minimum selling price |

835,001 |

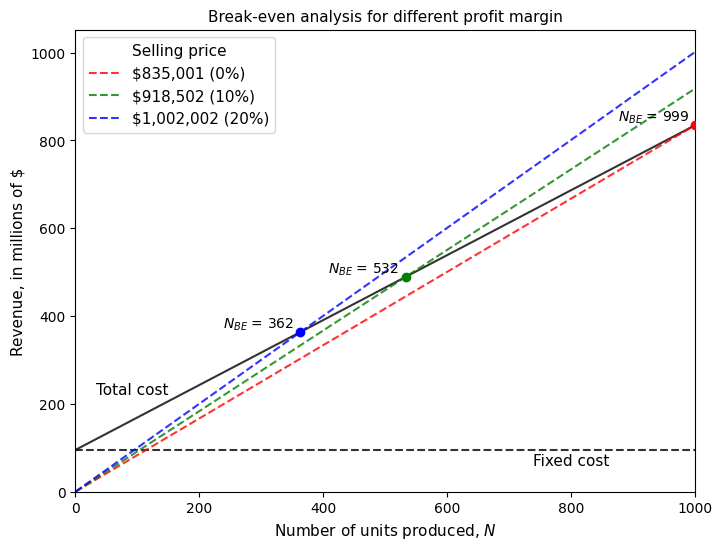

Break-even#

Once fixed and variable costs are known, break-even analysis can be performed. The number of units to be sold for break-even can be computed as

The total fixed cost is already known. The unit cost is simply the sum of the unit variable cost and liability insurance. Using above equation, \(N_{BE}\) can be computed by determining a suitable unit sales price. Below code block graphically illustrates \(N_{BE}\) for three different unit sales prices based on a profit margin of 0%, 10%, and 20%:

# Variables

num_aircraft = np.linspace(0,N,N+1,dtype=int)

total_cost = C_cert + (unit_var_cost + liability_ins) * num_aircraft

total_cost = total_cost/1e6

profit = np.array([0, 0.1, 0.2])

unit_price = min_selling_price * np.array([1,1.1,1.2])

colors = ["r", "g", "b"]

fs = 11

alpha = 0.8

# Plotting

fig, ax = plt.subplots(figsize=(8,6))

ax.axhline(y=C_cert/1e6, linestyle="--", color="k", alpha=alpha)

ax.plot(num_aircraft, total_cost, "k", alpha=alpha)

for i, price in enumerate(unit_price):

total_revenue = price * num_aircraft / 1e6

N_BE = C_cert / (price - (unit_var_cost + liability_ins))

ax.plot(num_aircraft, total_revenue, f"{colors[i]}--", label=f"${int(price):,} ({int(profit[i]*100):,}%)", alpha=alpha)

ax.scatter(N_BE, N_BE*price/1e6, zorder=10, color=colors[i])

ax.annotate("$N_{BE}$ = " + f"{int(N_BE):,}", (N_BE-10,N_BE*price/1e6), ha="right", va="bottom", zorder=10)

# Annotations

ax.annotate("Fixed cost", (800,C_cert/1e6-25), fontsize=fs, ha="center", va="center")

ax.annotate("Total cost", (150,250), fontsize=fs, ha="right", va="top")

# Asthetics

ax.legend(fontsize=fs, title="Selling price", title_fontsize=fs)

ax.set_xlim(left=0, right=N)

ax.set_ylim(bottom=0)

ax.set_title("Break-even analysis for different profit margin", fontsize=fs)

ax.set_xlabel("Number of units produced, $N$", fontsize=fs)

_ = ax.set_ylabel("Revenue, in millions of $", fontsize=fs)

When there is no profit i.e. aircraft is sold at its minimum selling price, the \(N_{BE}\) is equal to the number of airplanes assumed to be produced over 5-year period. As the profit margin increases, the number of units for break-even also decreases. However, one should carefully determine the selling price based on market conditions. Based on the above analysis, for a unit price of $900,000, the number of aircraft to be sold for recovering the cost wil be approximately 550. This concludes the unit cost estimation, next step is to determine the operating costs.